History and highlights of the year

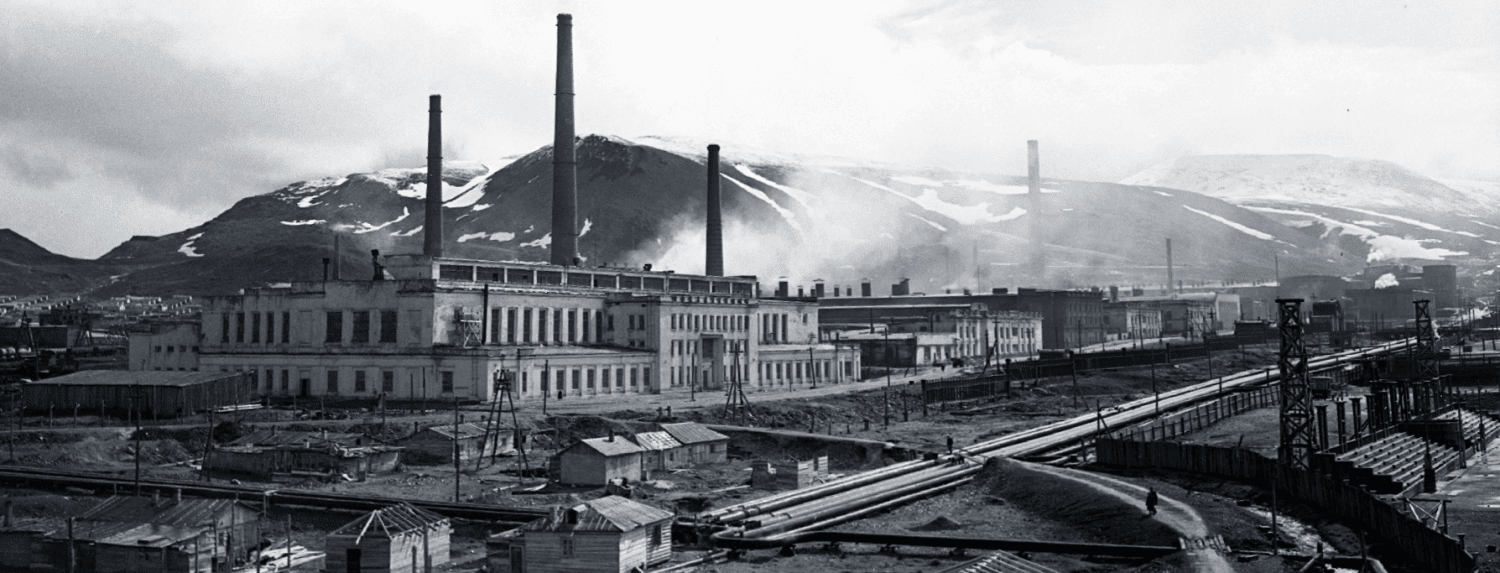

Construction of Norilsk Metallurgical Plant on the Taimyr Peninsula and of Severonickel Plant on the Kola Peninsula commenced. The first batches of converter matte and saleable nickel were produced in 1939.

By late 1953, Norilsk Plant producedOf the Soviet Union’s total output.

New deposits were developed and new facilities put online

- Major sulphide deposits of copper‑nickel ores of the Talnakh Ore Cluster were discovered.

- The construction of mines and the town of Talnakh started on the Taimyr Peninsula.

- The first batch of carbonyl nickel was produced at Severonickel Plant.

- Komsomolsky, Oktyabrsky, and Taimyrsky Mines were launched; Talnakh Concentrator and Nadezhda Metallurgical Plant were commissioned. Severonickel Plant celebrated first production of electrolytic copper.

Company transformation

The Norilsk Nickel State Concern for the Production of Precious and Non‑Ferrous Metals was transformed into RJSC Norilsk Nickel and privatised. In 2001, the Company was restructured, with shareholders owning a combined 96.9% stake in RJSC Norilsk Nickel exchanging their shareholdings for shares in OJSC MMC Norilsk Nickel. Company shares started trading on the RTS and MICEX stock exchanges, and first American Depositary Receipts (ADRs) were issued in June.

Implementing a new strategy

Vladimir Potanin and his new management team took the helm of the Company. The Board of Directors adopted a new long‑term development strategy focused on world‑class assets. A mining and processing plant, the largest greenfield project in the Russian metals industry, was constructed from scratch in the Trans‑Baikal Territory. At that time, a programme was launched to improve the environmental conditions across the Company’s footprint, including the shuttering of Nickel Plant in Norilsk, the launch of the Sulphur Project to drastically reduce sulphur dioxide emissions, and the closure of obsolete metallurgical facilities in the Murmansk Region.

Moderate growth strategy

The Company is pursuing a strategy of moderate growth amid global uncertainty, while continuing to comprehensively develop its mining capabilities and expand its processing capacities. Nornickel is also focused on implementing its environmentally friendly growth strategy, which includes the completion of the Sulphur Project in 2027 and a drastic reduction in emissions across all production sites. Nornickel is doubling down on operational efficiency by transforming its governance system. Notable accomplishments to date include the launch of the Sulphur Project at Nadezhda Metallurgical Plant, the development of Eurasia’s deepest ore horizons, and first production at the Glubokaya shaft of Skalisty Mine from a depth of almost 2 km.

The Company’s commitment to transparency is demonstrated by the publication of its inaugural Climate Change Report, detailing its climate action and climate adaptation initiatives from 2021 to the present, and the launch of an automatic air quality monitoring system in Norilsk. Nornickel’s strong commitment to social responsibility is evidenced by both a 10% wage indexation and the full retention of its benefits package as well as by the launch of the Digital Investor corporate programme, which awards employees digital financial assets linked to the market value of Nornickel shares.

An updated environmental and climate change strategy was approved, comprising more than 150 initiatives worth over RUB 500 billion to be implemented by 2031.

A flash smelting furnace revamp was completed at Nadezhda Metallurgical Plant, resulting in a 25% capacity increase.

The Company inaugurated a Battery Technology Centre in Saint Petersburg, marking a new phase in its efforts to advance technological capabilities in the promising field of nickel‑bearing cathode active materials (CAMs) – a key component in modern batteries.

A major deal was signed with RusHydro to purchase 10 thousand carbon units generated by RusHydro’s climate project for converting Vladivostokskaya CHPP‑2 from coal to gas. The Company can retire carbon units from its balance sheet as needed, thereby reducing its reported gross greenhouse gas (GHG) emissions and potential future carbon tax liabilities.

The Moscow Exchange launched trading in Nornickel’s platinum and palladium, providing investors with portfolio diversification opportunities and direct access to the PGM market. The new instruments will allow investors to respond effectively to market shifts and capitalise on the upside potential of platinum and palladium prices.

New wells launched at the Pelyatkinskoye field helped enhance the reliability of gas supply to the Norilsk Industrial District. For the first time in a decade, the Company commenced drilling new wells. This large‑scale project, with investments of approximately RUB 10 billion, is a key component of development strategy of Energy Division.

Nornickel and its employees have extended the Collective Bargaining Agreement until 2027. The Company’s social commitments continue to go beyond the requirements of labour legislation, and its benefits package remains one of the best in the industry. The new version of the collective bargaining agreement embodies one of Nornickel’s core values – care for people – and complements traditional support measures with new initiatives based on employee suggestions.

Hundreds of thousands of sturgeon fingerlings were released into the Yenisei River. The fish stocking project for the Yenisei River, implemented under a cooperation agreement with the Russian Federal Agency for Fishery, plans to release 510 million juvenile fish of valuable species – including sturgeon, muksun, broad whitefish, whitefish, and nelma – into water bodies of the Norilo‑Pyasinskaya lake and river system between 2033 and 2050.

An air quality monitoring system was launched in Norilsk, integrating various sensors and devices into a single platform to provide round‑the‑clock monitoring of ambient air across different districts of Norilsk, Talnakh, and Kayerkan. The system enables real‑time assessment of air pollution levels.

The governance model was amended, with the two key operational units – the Norilsk and Kola Divisions – merged into the Polar Division to establish a flatter management structure that enables faster decision making. In addition to the Polar Division, three other divisions continue to operate within Nornickel’s structure: the Trans‑Baikal, Energy, and Sales Divisions.

Nornickel has implemented its first climate project and issued carbon units. Under the project, the main ventilation units at Severny Mine in the Murmansk Region were converted to electric heating, enabling the retirement of the legacy fuel oil‑fired boiler plant while also reducing GHG emissions by nearly 17,500 tonnes of CO2 equivalent.

A major milestone in 2024 was the validation of the Sulphur Project’s effectiveness at Nadezhda Metallurgical Plant after its first line was launched in late 2023. Throughout 2024, Nornickel gradually commissioned core gas recovery equipment to support the project’s ramp up to design capacity and successfully launched the second process line. The project helped reduce sulphur dioxide emissions by 390 kt, with a 99.1% efficiency in treating sulphur‑rich gases, as confirmed by the Federal Service for Supervision of Natural Resources (Rosprirodnadzor). The Sulphur Project is aimed at dramatically reducing sulphur dioxide emissions in the Norilsk Industrial District and improving the quality of life for Norilsk residents.