Environment and climate

Contribution to the UN SDGs

Reducing environmental impact remains one of Nornickel’s strategic priorities. The Company strictly complies with environmental legislation, identifies and manages environmental risks, regularly trains employees, improves environmental controls, streamlines production processes, and takes biodiversity conservation and restoration measures.

Strategy

In 2024, the Company updated its Environmental and Climate Change Strategy, extending its planning horizon to 2035 and introducing new initiatives, including the construction and modernisation of wastewater treatment facilities, biodiversity restoration efforts, replacement of legacy dust collection equipment, and the commissioning of mobile waste treatment units. The updated strategy also reaffirms Nornickel’s commitment to reducing greenhouse gas emissions across its footprint and contributing to national climate goals.

In addition, the document adjusts targets for disturbed land rehabilitation and sulphur dioxide emission reduction. While the target for sulphur dioxide capture was 377 kt in 2024, it is set to double to 736 kt in 2025 and increase to 922 kt from 2026 onwards.

| Focus areas | 2031 targets |

|---|---|

| No interregional or national emergencies | |

| Air | Reduction of SO2 emissions by 90% to 213 ktpa |

| Water | 100% compliance with regulatory requirements for pollutant concentrations in wastewater 100 % compliance with freshwater withdrawal limits |

| Tailings storage facilities and waste | 100% compliance with regulatory requirements for waste disposal facilities |

| Land | Rehabilitation of 3,996 ha of disturbed land |

| Biodiversity | Achievement of net zero biodiversity losses as a result of the Company’s operations (∆ Integrated Ecosystem Health Indicator (IEHI)) |

Environmental management

In place since 2005, the Company’s environmental management system is part of the integrated quality and environmental management system. This ensures coordination between all environmental matters and other areas, enhancing the Company’s overall performance on environmental safety.

Environmental audits

The Company confirms the compliance of its environmental management system with ISO 14001:2015 by engaging Bureau Veritas Certification Rus (BVC) to conduct surveillance audits annually and recertification audits every three years. Bureau Veritas Certification Rus operates in Russia under the accreditation of the Egyptian EGAC, which is a full signatory and participant of the IAF MLA Multilateral Recognition Arrangement of the International Accreditation Forum..

In 2023, based on the results of a recertification audit, the Company received a certificate of conformity valid until 12 January 2027. The first surveillance audit of the seventh certification period conducted in 2024 established full conformity with ISO 14001, and the certificate was extended for another year.

At the end of 2024, 51% of Group assets By average headcount. were certified to the ISO 14001 environmental standard.

ISO 14001:2015 certificate

| Certified assets | Status |

|---|---|

| Head Office and branches Kola site |

|

| Foreign site |

|

| Trans‑Baikal Division |

|

Air

One of the Company’s principal environmental impacts is the significant emissions of sulphur dioxide during the smelting of sulphide concentrates.

Sulphur Project

Nornickel’s development strategy is to transform the Company into an environmentally safe business, including by implementing the Sulphur Project at the Kola and Norilsk production sites. The Sulphur Project is a large‑scale initiative to recover sulphur dioxide from off‑gases of flash smelting furnaces.

At the Norilsk site, it is implemented at Nadezhda Metallurgical Plant and includes technological upgrades to recover sulphur dioxide from off‑gases of flash smelting furnaces by converting them into sulphuric acid and then neutralising it with limestone. The resulting gypsum pulp from the neutralisation process is stored in a dedicated gypsum storage facility.

In October 2023, the first process line was launched, with 7.5 kt of sulphur dioxide recovered during pre‑commissioning before the end of the year. In September 2024, the Company launched comprehensive testing of the second process line, boosting sulphur dioxide recovery from gases to approximately 390 kt. Preliminary assessments of the technologies applied in the project demonstrated a recovery efficiency exceeding 99%, a figure confirmed by government agencies during control and oversight inspections.

At the Kola site, the Sulphur Project helped reduce sulphur dioxide emissions by over 90% compared to the 2015 base year – exceeding the target of 85%. From 2020 to 2024, emissions remained virtually unchanged thanks to production reconfiguration measures and the adoption of the best available technologies.

| Indicators | 2020 | 2021 | 2022 | 2023 | 2024 |

|---|---|---|---|---|---|

| Sulphur dioxide (SO2) | 1,911 | 1,601 | 1,778 | 1,671 | 1,269 |

| Nitrogen oxide (NОx) | 10 | 11 | 10 | 6 | 6 |

| Particulate matter | 15 | 9 | 11 | 11 | 11 |

| Other pollutants | 33 | 25 | 21 | 20 | 21 |

| Total | 1,968 | 1,647 | 1,819 | 1,708 | 1,307 |

Water

In 2024, RAEX ranked Nornickel among the leaders in water stewardship.

Company enterprises are located in regions with sufficient water resources. In 2024, no water stress was reported, as both enterprises and local populations were supplied with adequate water volumes.

Nornickel’s operations are associated with the following water‑related risks:

- Pollution of water bodies resulting from tailings or petroleum product spills

- Pollution of water bodies due to poor performance of wastewater treatment facilities

- Depletion of water bodies caused by withdrawals exceeding permitted limits

FOR PRODUCTION ACTIVITIES WITH THE EXCEPTION OF MINE WATERS.

The Company is committed to the responsible and sustainable use of water resources and the prevention of water body pollution. To this end, the Company regularly monitors groundwater at production sites and is designing systems to collect and treat mine‑impacted water. All facilities using water monitor water bodies and water protection areas. Nornickel does not withdraw water from protected natural sites and strictly complies with water withdrawal limits.

Nornickel’s key production facilities operate closed‑loop water systems. Water is mostly withdrawn from surface and underground sources, but also includes third‑party wastewater and natural inflow. In 2024, water withdrawal increased by 3.6 Mcm y‑o‑y, including a 3.5 Mcm rise in freshwater withdrawal. Natural water inflow accounted for 14.8% of total water withdrawal in 2024.

An impressive 81% of all water used by the Company was recycled and reused, including produced and mine water used to neutralise sulphuric acid under the Sulphur Project.

Water consumption and wastewater discharge in 2024

Water withdrawal

321 Mcm

- 218 Mcm

Surface sources - 26 Mcm

Underground sources - 17 Mcm

Wastewater - 50 Mcm

Natural water inflow - 10 Mcm

Other

Consumption

1,224 Mcm

= 232 (freshwater) + 992 (reused and recycled water)

- 72 Mcm

reused water (6%) - 920 Mcm

recycled water (75%)

Wastewater discharge

224 Mcm

- 145 Mcm

Clean - 10 Mcm

Treated - 31 Mcm

Insufficiently treated - 38 мMcm

Contaminated

Wastewater discharge to water bodies primarily stays within permitted limits and has no material impact on biodiversity. In 2024, wastewater discharge increased by 52% due to the discharge of standard‑quality treated water used for cooling at CHPP‑1.

Nornickel takes all possible measures to ensure that pollutant concentrations in wastewater comply with regulatory requirements. All domestic sewage discharges are routed through biological or physico‑chemical treatment facilities. The volume of untreated wastewater decreased by 3.4 Mcm in 2024. The mass of pollutant discharges decreased by 43% to 89.9 kt.

Nornickel consistently invests in improving the efficiency of existing water treatment systems and building new ones, and it regularly assesses its impact on water resources. The relevant measures include:

- wastewater inventory

- assessment of wastewater quality at accredited laboratories at legally mandated intervals

- monitoring of wastewater discharge volumes and quality at discharge sites

- observation of surface water bodies at control points upstream and downstream of discharge sites

- monitoring of wastewater treatment processes at treatment facilities and implementation of organisational and technical measures to improve treatment effectiveness.

Impacts from water transport

The Company takes steps to reduce fuel consumption by its water transport and to prevent contamination of the Dudinka and Yenisei Rivers. It also supports biodiversity by organising the release of fish fry into natural habitats.

Waste

Of the waste generated in the Company’s own activities, 99% is classified as non-hazardous. This includes rock and overburden, tailings, metallurgical slags, and ferrous cake. Ore extraction waste is placed in waste rock dumps and used for backfilling mined-out underground stopes and open pits, as road fill, or for reinforcing tailings dams. Of the total waste generated, gangue accounts for 80%, tailings for 18%, and recycled or reused waste makes up 17%.

Key methods for reintegrating waste into own production include recycling in smelting furnaces, oil recovery, use as flux, incorporation into furnace charge materials, and application in construction.

Waste generation remained virtually flat year-on-year in 2024.

Waste disposal

The Company currently operates six tailings storage facilities: four at the Norilsk site, one at the Kola site, and one in the Trans-Baikal Division.

All of them are situated at a considerable distance from production sites and human settlements. Nornickel recognises that tailings storage facilities are high-risk assets with the potential for significant environmental impacts and consequences for the quality of life of local communities. The Company has developed a Tailings Management Policy and conducts regular monitoring of the condition of tailings dams, discharge sites, and adjacent areas.

As part of the Sulphur Project, a gypsum storage facility was also constructed and is currently in the pre-commissioning stage. The facility is designed for the safe storage of gypsum pulp.

Land and biodiversity

Land

The Company’s priority in land conservation is to reduce and, where possible, prevent negative impacts associated with its operations.

| Indicators | 2022 | 2023 | 2024 |

|---|---|---|---|

| Land disturbed at the beginning of the reporting period | 16,694 | 16,906 | 17,225 |

| Land disturbed during the reporting period | 317 | 297 | 199 |

| Reclamation | 75 | 15 | 71 |

| Land disturbed at the end of the reporting period | 16,936 | 17,188 | 17,353 |

| Indicators | 2022 | 2023 | 2024 |

|---|---|---|---|

| Land rehabilitated, including: | 498 | 245 | 235 |

| 12 | 5 | 9 |

| 154 | 79 | 73 |

| 284 | 112 | 87 |

| 48 | 49 | 66 |

Nornickel regularly participates in landscaping and greening initiatives in the regions where it operates. The Company has developed an action plan for the rehabilitation of disturbed areas, which includes clean‑up and improvement of municipal areas adjacent to motorways, protection of water bodies and water protection areas, and the enhancement of local holiday camps. These initiatives are implemented in cooperation with local authorities and employee volunteers from Nornickel.

Biodiversity conservation

For many years, Nornickel has actively supported biodiversity conservation and worked to preserve species in the regions where it operates.

Since 2022, the Company has been working in collaboration with scientists from the Russian Academy of Sciences (RAS) to assess biodiversity and organise expeditions for comprehensive studies of ecosystems in areas where its mining, production, and energy operations are located. These are the largest ecosystem research projects since the Soviet era. To date, three regions have been studied: the Trans‑Baikal Territory, the Murmansk Region, and the Taimyr Peninsula.

Salmon foundation for preserving the biodiversity of the Kola Peninsula cleaned the river and carried out a series of scientific studies.

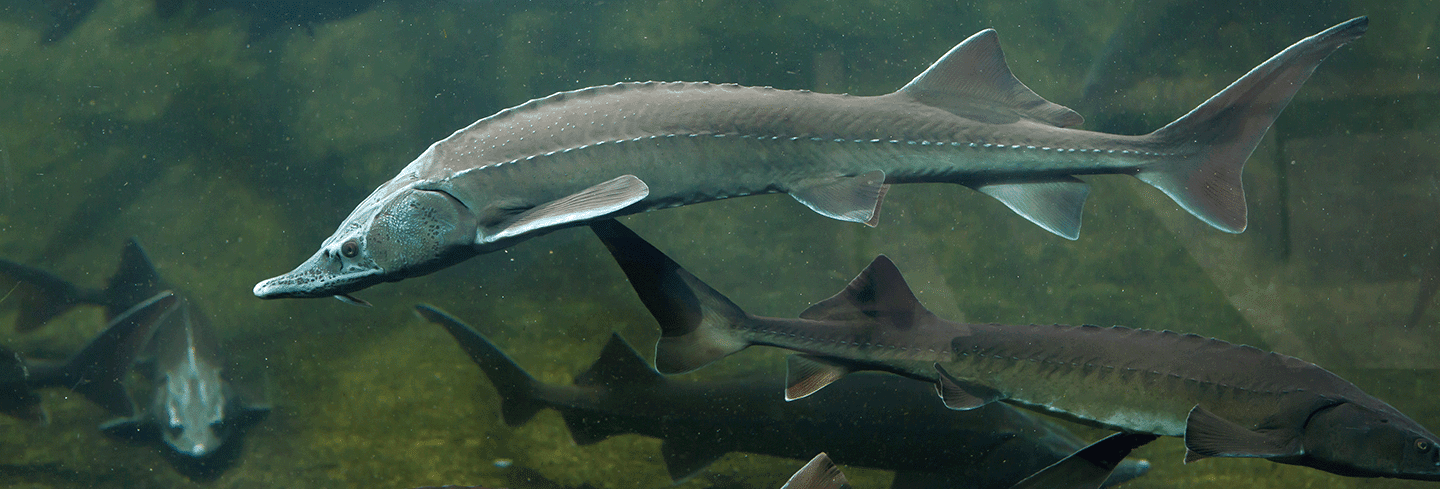

In the Trans‑Baikal Division, nearly 150 thousand common carp fry were released into Lake Shaksha in the Ivano‑Arakhleisky Nature Park during 2024 to help restore the species’ declining population.For many years, the Company has also operated a programme for the incubation and release of valuable fish species into water bodies in the Krasnoyarsk Territory to replenish their populations. Valuable fish species, including those listed in the Red Data Book, are bred at facilities operated by specialised contractors, with juvenile fish later released into natural water bodies.

Since 2023, the Company has been involved in efforts to preserve the gyrfalcon population under an agreement with the Russian Ministry of Natural Resources and Environment.

Since 2022, the Kola site, in collaboration with the Institute of Biology of the Kola Science Centre of the Russian Academy of Sciences, has been involved in fish stocking of local water bodies. Dozens of hatchery nests have been installed in the Monchegorsk area to support egg incubation and the development of juvenile fish. In 2024, approximately 180 thousand fish eggs were placed in these hatcheries. Prior to stocking the Moncha River, the Murmansk

Since 2023, under an agreement between the Company, the Federal Agency for Fishery, and the Russian Federal Research Institute of Fisheries and Oceanography, a team of scientists has been conducting research on Lake Pyasino, the Pyasina River, and the Ambarnaya, Norilskaya, Daldykan, Agapa, and Dudypta Rivers. Monitoring of the condition of aquatic bioresources and their habitats will support the development of recommendations for fish population recovery. During the 2024 expedition, 16 Siberian sturgeon were caught in the Pyasina River – the first recorded catch since 1982. The species had previously been considered extinct on the Taimyr Peninsula.

Cooperation with nature reserves

Nornickel supports nature reserves in the regions where it operates and does not conduct operations within or near protected areas:

- In the Murmansk Region, the Pasvik, Lapland, and Kandalaksha Nature Reserves are located 10 to 90 km away from the Kola site’s production facilities

- In the Krasnoyarsk Territory, the buffer zone of the Putoransky Nature Reserve lies 80 to 100 km from Nornickel’s production sites

- In the Trans‑Baikal Territory, the Daursky State Nature Biosphere Reserve is located 250 km from the Trans‑Baikal Division’s production facilities

Nornickel environmentalists, experts from the Siberian Branch of the Russian Academy of Sciences, and representatives of the nature reserves wrapped up the Big Scientific Expedition, which helped to:

- update the delineation of the impact areas of the Company’s facilities and assess biodiversity both in areas adjacent to production sites (within the impact areas) and in locations beyond the radius of negative impact, where plant and animal communities typical of the region are found

- identify the key factors and extent of negative impact of the Company’s facilities on local ecosystems

- record the diversity of plant, vertebrate, and invertebrate species and calculate an integrated ecosystem health indicator to evaluate biodiversity net gain

- identify indicator species reflecting the condition of local ecosystems.

In 2024, the Company continued to cooperate with nature reserves on the Taimyr Peninsula. As part of this cooperation, the endemic Putorana snow sheep – listed in Russia’s Red Data Book – was studied, and a conservation strategy for the species was developed.

In the Murmansk Region, the Company works with the Pasvik and the Lapland Nature Reserves. To raise awareness about the preservation of the reindeer population in the Lapland Nature Reserve, Nornickel participates in the Let’s Save Reindeer Together project. With the Company’s support, eco‑trails were created in the reserve, guest houses and a visitor centre were built, and two books were published – one about the founders of the reserve, and a children’s book titled Secrets of the Lapland Nature Reserve.

In the Pechengsky District, the Company supports a unique initiative by the Pasvik Nature Reserve to establish a Freshwater Pearl Mussel Reintroduction Centre. Plans for population restoration extend beyond the district to other municipalities in the region. At the time of writing this Report, a project roadmap was under development and suitable habitats were being studied in the Paz, Kaskamajoki, Laukkujoki, and Nilijoki river basins.

The Company also plans to propose broader biodiversity cooperation with the reserve, drawing on the experience it has gained through long‑standing partnerships with other reserves in the region. Plans include the joint implementation of volunteer environmental research projects.

In 2024, the Company supported a rescue operation for an injured humpback whale, a Red Data Book species, in the Barents Sea. The whale was entangled in remnants of fishing nets and could not fully open its mouth, a condition that would have led to certain death. Thanks to the joint efforts of the Company, Rosprirodnadzor, and the Murmansk Region emergency response team, the animal was successfully saved.

In the Trans‑Baikal Territory, the Company contributed to the uninterrupted work of inspection teams tasked with protecting mass gatherings and breeding areas of rare species, and supported the systematic winter census of the Mongolian gazelle (a hoofed mammal of the Procapra genus, Bovidae family) in the Daursky Biosphere Reserve. In addition, an eco‑trail was created at the planned Krasnaya Gorka natural monument, a protected area of regional significance.

Climate

Our approach

Nornickel strives to reduce greenhouse gas emissions in its regions of operation and contributes toward Russia’s national climate goals. The key measures to achieve carbon neutrality include production upgrades, gangue mineralisation in tailings storage facilities, energy efficiency efforts, steps to increase the share of renewables and low‑carbon‑footprint fuels in the energy and transport sectors, and climate projects.

The Company continues integrating its climate risk and risk factor management system into its business processes in accordance with the TCFD and COSO recommendations.

To assess risks and opportunities arising from the global energy transition, Nornickel has developed three own scenarios for global economy and climate change until 2060.

Rapid Transition

Probability: 20%

Low-carbon development scenario

+1.8 °С

Sustainable Palladium

Probability: 75%

Continuation of current socioeconomic and technological trends

+2.0 °С

Global Growth

Probability: 5%

Abandoning efforts to curb climate change with further economic growth fuelled by hydrocarbons

+2.4 °С

The Company has chosen the Sustainable Palladium as its baseline scenario, according to which traditional industries are expected to remain centre stage along with the growing green economy. In particular, internal combustion engine vehicles are expected to retain a large market share, supporting a steady long‑term demand for palladium. The other two scenarios are used by the Company to stress‑test climate‑related risks.

For more details on climate‑related risks and opportunities, please see the Risk Management section of this Report.

Greenhouse gases

Since 2020, the Company has been calculating its direct and indirect greenhouse gas emissions (Scope 1 + 2), including the emissions allowance for the Sulphur Project. In view of the upcoming reconfiguration of the Copper Plant, which will substantially cut the pollutant emissions, the Company adjusted its calculations of greenhouse gas emissions by excluding the emissions allowance of the Sulphur Project for the Copper Plant that was previously accounted for in the Group’s gross emissions Data on GHG emissions from the Sulphur Project of Nadezhda Metallurgical Plant will be updated once the project is ramped up to its design capacity..

In 2024, direct and indirect greenhouse gas emissions from operations (Scope 1 + 2) amounted to 7.5 mln t of CO2 equivalent The emissions Scope 2 were calculated using the location‑based method. Also GHG emissions (Scope 1+2) were, includeding the emissions allowance for the Nadezhda Metallurgical Plant under the Sulphur Project and excludeding emissions from heat and electricity supplies to household consumers. , and 0.4 mln t of CO2 equivalent was directly removed through gangue mineralisation in tailings storage facilities.

In 2024, the Group’s greenhouse gas emissions decreased due to the following factors:

- lower per unit fuel consumption for heat and electricity generation as a result of optimising equipment operation modes at combined heat and power (CHP) plants

- lower heat and electricity generation due to a warmer winter in the Norilsk Industrial District

- updating of regional СO2 emission factors for electricity supply within the energy systems of the Murmansk Region and Trans‑Baikal Territory.

Energy indirect GHG emissions (Scope 2) were calculated using the location‑based method, including regional emission factors. Regional emission factors were updated to take into account new commissioned renewable facilities in the Company’s regions of operation.

The Trans‑Baikal Division and RusHydro signed a bilateral agreement to purchase 124.9 mln kWh of electricity generated by RusHydro hydropower plants, driving Scope 2 GHG emissions down by more than 126 kt of CO2 equivalent in 2024.

The world is seeing a rapidly emerging and growing global carbon market, where industrial companies issue carbon units when implementing climate projects. Nornickel participates in the national carbon market and plans to enter the international one. In 2024, Nornickel and RusHydro entered into the largest carbon unit sale and purchase transaction in the Russian market, and the Company also started issuing its own carbon units, with the Kola enterprise switching main ventilation units at Severny Mine to electric heating. A total of 17,483 carbon units are planned to be released (with 14,193 carbon units currently outstanding).

As part of its climate action, Nornickel is considering environmental and climate projects in its regions of operation.

To reduce its direct and indirect energy GHG emissions, the Company monitors and manages emissions and upgrades production. The Company plans to commission its own generation facility – a solar power plant in the Trans‑Baikal Territory, in the second half of 2025 and is also working on switching its mining transport equipment to alternative fuels.

As removal of atmospheric carbon dioxide is one of the most important actions to combat the global climate change, another focus area for reducing greenhouse gas emissions is gangue mineralisation in tailings storage facilities. Mineralisation is one of the most effective CO2 sequestration methods, which involves chemical reactions between carbon dioxide, water, and rocks.

These reactions form stable carbonate minerals such as calcite/aragonite, dolomite, magnesite, and siderite that can store carbon for thousands of years. The method has great potential for long‑term CO2 storage in stable mineral forms, making it attractive for large‑scale application. Nornickel’s tailings storage facilities are unique in that they are equipped to absorb greenhouse gas emissions, including carbon dioxide. The amount of direct GHG absorption depends on the volume of waste rock generated during the reporting period and disposed of at the Group’s tailings storage facilities.

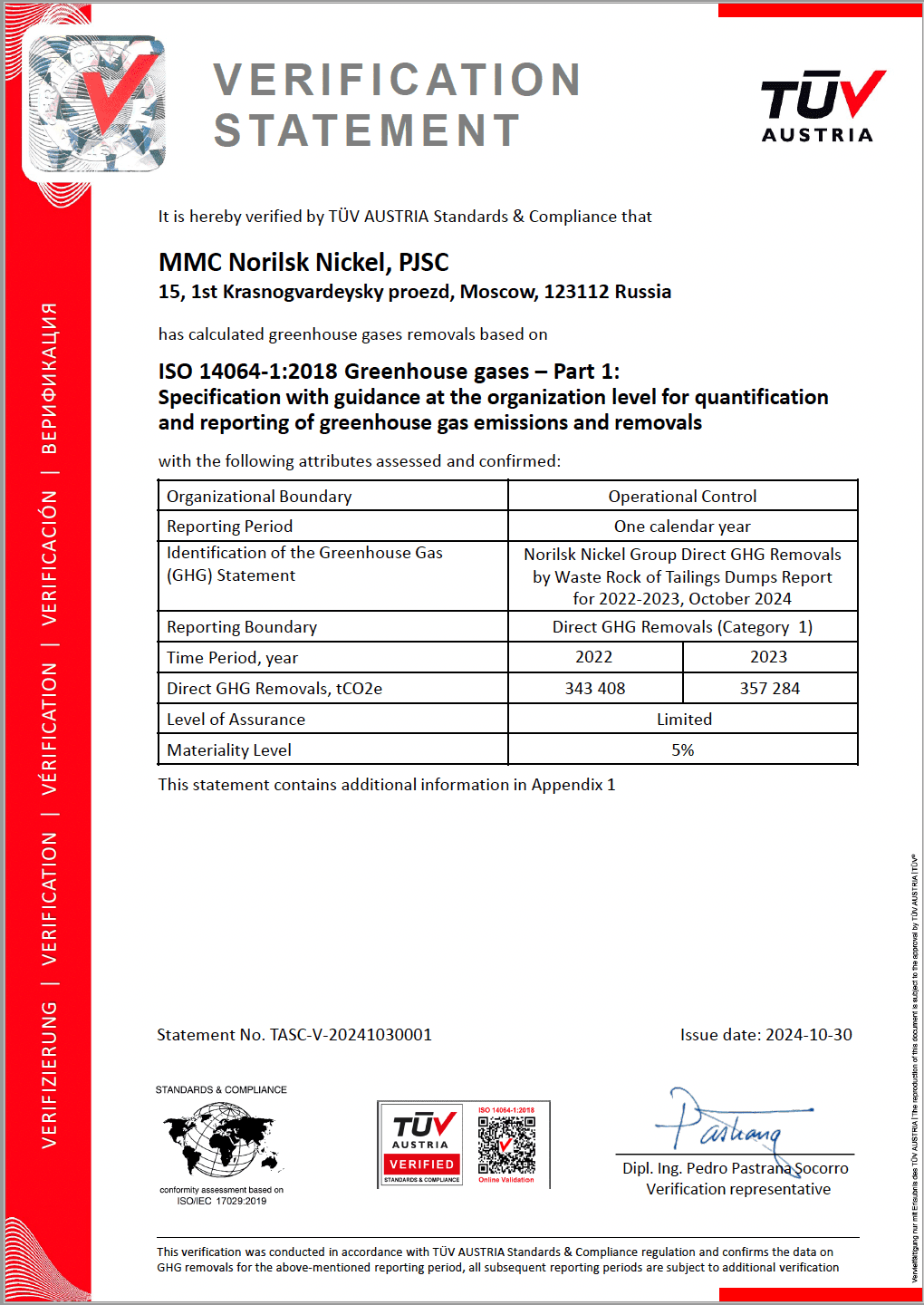

The Company has certified the methodology for calculating direct GHG absorption through gangue mineralisation in tailings storage facilities, unique in Russia, to GOST R ISO 14064‑1‑2021 Greenhouse gases. Part 1. Specification with guidance at the organisation level for quantification and reporting of greenhouse gas emissions and removals. Data on actual absorption for 2021–2024 have been verified by an international independent company.

Nornickel plans to develop this project, with detailed studies of artificial and active mineralisation in tailings storage facilities scheduled to start in 2025. These processes have a considerable potential for GHG removal and will further be presented as climate projects.

In 2024, the Gangue Mineralisation – Greenhouse Gas Removal by Tailings Storage Facilities became one of the Best ESG Projects in Russia in the Climate Action. educing Greenhouse Gas Emissions category.

Nornickel’s key production facilities are located in the Norilsk Industrial District, in the Arctic Circle, and operate in sub‑zero temperatures for about eight months of the year. The district is isolated from the federal energy infrastructure, so Nornickel generates electricity and heat locally at its own generating facilities (100% owned by the Group). As a result, the bulk of GHG emissions comes from the Company’s energy assets. As Nornickel is the only producer of electricity and heat in the Norilsk Industrial District, the Company also fully meets the demand for energy and heat from social infrastructure facilities and the local population. The share of GHG emissions generated by infrastructure facilities and households in Nornickel’s regions of operation is on average 12% of total Scope 1 + 2 GHG emissions.

Scope 3

The Company annually quantifies its other indirect (Scope 3) GHG emissions, which originate outside the Group and are beyond the Group’s control or influence. The Company distinguishes between upstream and downstream Scope 3 emissions.

The bulk of upstream Scope 3 emissions is related to the purchase of raw materials and equipment from suppliers as well as energy and fuel consumption (to the extent not included in Scope 1 + 2).

Downstream emissions are associated with the transportation of the Company’s products from production assets to consumers and subsequent processing into finished products. In 2024, the Company updated the methodology for calculating downstream emissions to align it with new methodologies The Scope 3 Emissions Accounting and Reporting Guidance (2023) by the International Council on Mining and Metals (ICMM), ISO 14083:2023 Greenhouse gases – Quantification and reporting of greenhouse gas emissions arising from transport chain operations, Global Logistics Emissions Council (GLEC) Framework, Scope 3 GHG Emissions in the Nickel Value Chains. A Guide to Determine Nickel‑Specific Scope 3 GHG Emissions by the Nickel Institute, and industry best practices. . The 2024 assessment covered nickel, copper, palladium, platinum, copper and nickel intermediates, and iron ore concentrate sold outside the Group. The bulk of these emissions comes from intermediates sold outside the Group. Emission volumes are influenced by changes in sales volumes, the Group’s product and customer portfolio, and the geographic mix of product sales.

Scope 3 emissions are quantified in line with the GHG Protocol guidance for all categories relevant to the Group and the IPCC Guidelines for National Greenhouse Gas Inventories.

| Emissions by category | 2021 | 2022 | 2023 | 2024 |

|---|---|---|---|---|

| Scope 3 (other indirect GHG emissions) | 5.4 | 5.3 | 6.4 | 6.7 |

| Upstream, including: | 1.4 | 1.4 | 1.3 | 1.2 |

| 0.8 | 0.9 | 0.8 | 0.7 |

| 0.1 | 0.1 | 0.1 | 0.1 |

| 0.4 | 0.3 | 0.3 | 0.3 |

| 0.1 | 0.1 | 0.1 | 0.1 |

| Downstream, including: | 4.0 | 3.9 | 5.1 | 5.5 |

| 3.8 | 3.7 | 4.9 | 5.3 |

| 0.2 | 0.2 | 0.2 | 0.2 |

Renewables and energy efficiency

Powered by both external and own generation facilities, Nornickel’s production assets are sources of direct and indirect greenhouse gas emissions (Scope 1 + 2).

The Company’s own energy assets are located in the Norilsk Industrial District and use low‑carbon sources for energy generation, such as natural gas and renewable hydropower. Diesel fuel, fuel oil, petrol, and jet fuel are used by Nornickel’s transport assets. Use of coal by energy assets is minimised to only small amounts in certain production processes.

The Kola site and Trans‑Baikal Division source heat from their own boiler plants and purchase electricity in the wholesale electricity and capacity market (WECM).

The Company’s key renewable energy source is hydropower generated by the Group’s Ust‑Khantayskaya and Kureyskaya HPPs. In 2024, the share of renewables in total electricity generation stood at 54% for the Group and 58% for the Norilsk Industrial District. Renewable energy accounted for 12% of the Group’s total energy consumption.

The use of other renewables, such as solar and geothermal energy, within the Arctic Circle is impracticable as Nornickel’s core operating assets are located in regions with harsh climatic conditions.

Solar power

8 months a year – air temperatures below freezing point

100 days – duration of polar nights and twilights

70 days per year – sunny days

Geothermal energy

Permafrost: 300 to 500 m deep

Nornickel attaches great importance to improving the energy efficiency of its existing and future production sites. In 2024, the Company invested more than USD 350 million in upgrading its energy infrastructure. The investments cover multiple projects related to equipment replacement at thermal and hydropower plants and upgrades to fuel tank storage facilities, power grids, and gas pipelines.

Permafrost monitoring

The system developed by Nornickel to monitor permafrost and the facilities built on it enables assessments of the impact permafrost degradation has on the stability of engineering structures in regions of operation while managing related risks.

Climate change in the Arctic drives global‑scale challenges and poses a significant threat to the security of polar infrastructure.

In recent years, Nornickel focused on building a science‑based, practical framework for asset operation management. Deep monitoring wells were drilled in populated areas of the Norilsk Industrial District to study the permafrost soil temperature range and assess the impact of global climate change. A 200‑m well in the centre of Norilsk, where temperature measurements have been taken since as early as 1958, was restored and fitted with a thermistor string. Data from the well are sent twice a day to the Company’s Facilities Monitoring Centre. Observations showed that in 1958, the base of permafrost was at a 150 m depth, while now it is at 147.7 m. The pace of permafrost thawing at the depth of 10 m was also established: the temperature there has increased by 4 °C since record keeping began, which confirms the steady trend of global warming.

The technical condition of facilities built on permafrost in the Norilsk Industrial District is monitored to reduce the risk of emergencies. To date, more than 1.8 thousand automated sensors have been installed across 223 facilities to gauge soil temperature and displacement of individual elements, carry out an ongoing control of temperature and humidity in crawl spaces, respond to possible failures of heat and water supply systems, monitor for relative deformation of structures.

The Centre’s experts run a range of geotechnical surveys, including visual inspections, geodetic monitoring, and manual measurement of groundwater level and foundation soil temperature. All data is fed into the Norilsk Division’s information and diagnostic system in real time and is used to monitor the safe operation of buildings and structures not only at the Norilsk site, but also at the Energy Division enterprises. The automatic monitoring system enables data analysis, including tracking of all deviations that reduces response time, as well as registration of soil and air temperature increase trends in crawl spaces and proactive actions to prevent any adverse effects. The system is also a database that contains all the information about such buildings: engineering surveys, design documents, related comprehensive inspections, and other materials. The system enables communications with property owners to issue and check compliance with recommendations as well as generate reports on a lot of metrics. Currently, the information and diagnostic system covers 17 Company enterprises and more than 600 employees.

A new approach based on the methods of mathematical modelling of thermal and mechanical interaction was developed to assess the impact of climate change on the stability of facilities in the Norilsk Industrial District. It relies on the climate change forecast across the Company’s footprint, prepared by leading research institutions. This approach is currently being tested at the Company’s critical facilities covered by the automatic monitoring system.

Background monitoring

Nornickel was the first Russian commercial organisation to set up its own regional system of background permafrost monitoring. The data obtained can be used to supplement the database on the condition and changes of permafrost in the natural environment, quantitatively predict changes in permafrost conditions, and assess natural and anthropogenic impacts on the soil temperature.

Thus, the Company now has geotechnical and background monitoring data that support informed and economically sound decisions regarding further operation of assets.

To date, studies have covered an area of about 8 thousand sq km stretching from the Norilsk Industrial District to Dudinka, and identified 11 testing grounds that best reflect the diversity of landscape and geocryological conditions. In 2023–2024, the Company drilled 20 monitoring wells with a depth of 10 to 20 m and three wells with a depth of 200 m to assess permafrost characteristics and determine the parameters of terrestrial heat flow. Before that in 2022, Nornickel also drilled five 200‑m wells in populated areas as part of its permafrost monitoring programme. The drilled wells are equipped with automated thermometric equipment that transmits data to the central data collection and processing server. Selected testing grounds are subject to monitoring of not only soil temperature but also risks of dangerous cryogenic processes by geophysical and geodetic methods. Fedorovsky Polar State University has equipped several testing grounds to hold winter and summer field schools to study permafrost.

In 2023, the background permafrost monitoring system received the National Environmental Prize named after V.I. Vernadsky, and in 2024, it won the Green Eurasia climate competition and received the GenerationS Innovation Award (GIA) for corporate innovations in Russia.